5S SERVICES

"ABOUT THIS SERVICE"

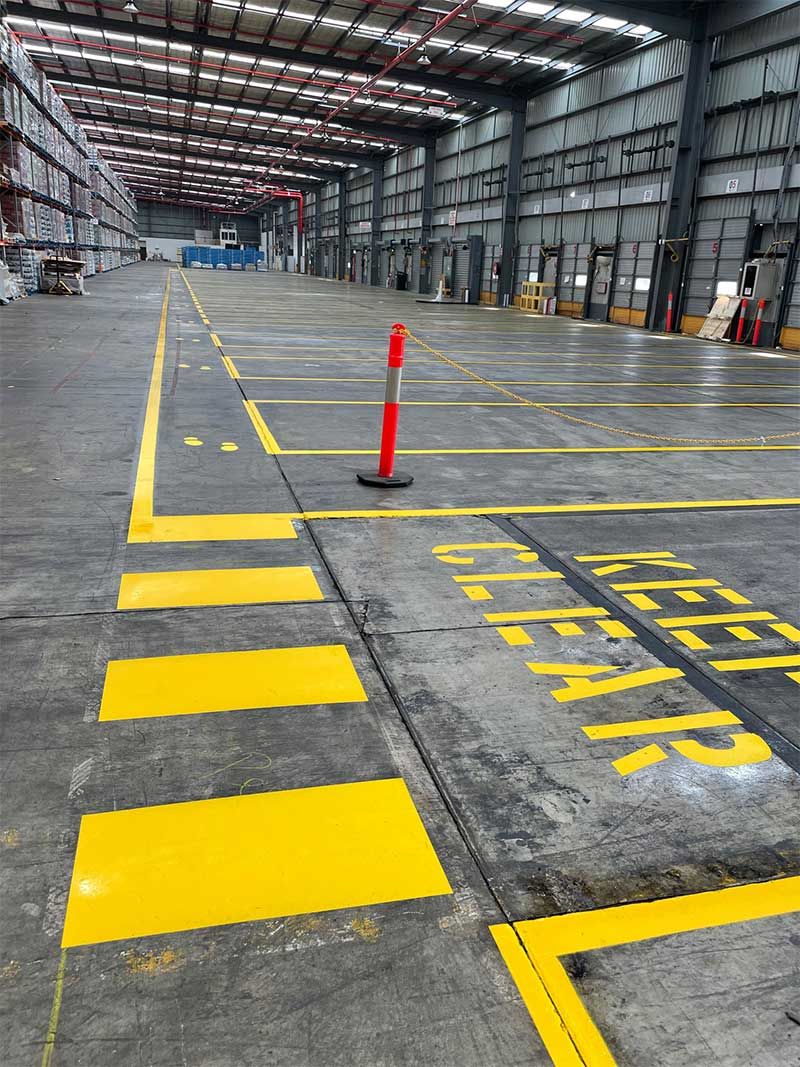

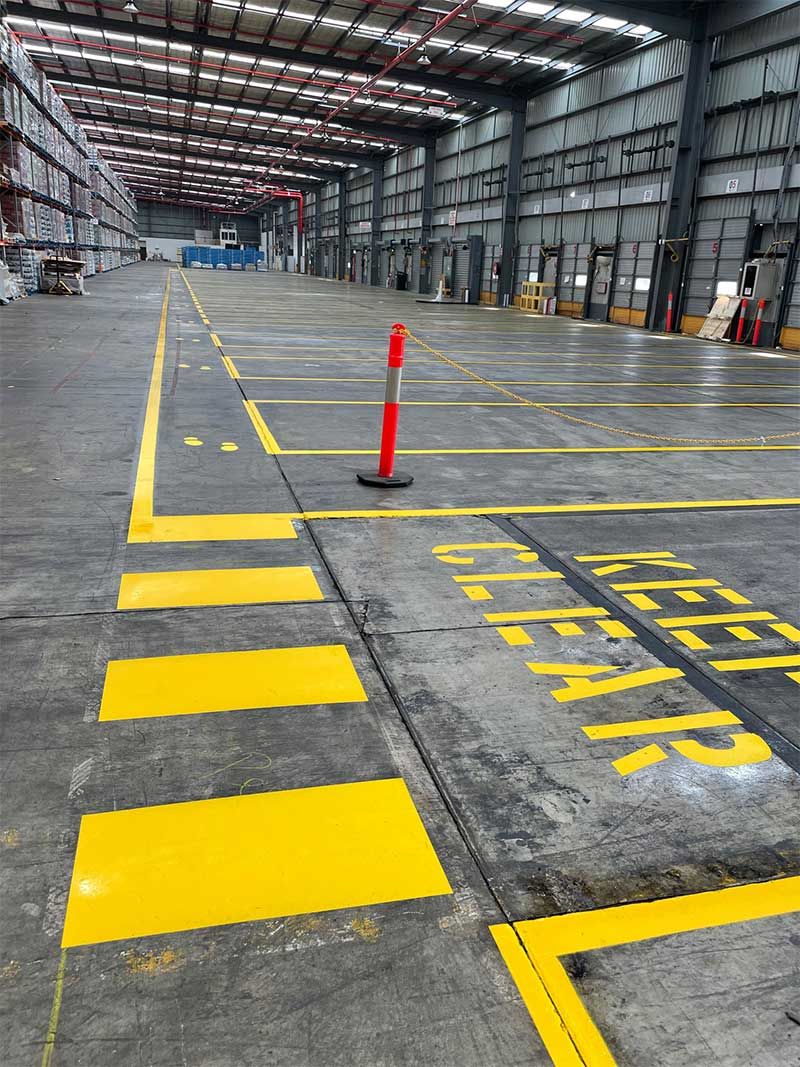

A 5S methodology is a systematic approach that aims to create a clean, organized, and safe workspace in order to optimize productivity and reduce waste.

It is designed to improve the overall quality of the work environment, both physically and mentally, and can be applied to any work area that is suited for visual control and lean production.

The 5S condition of a work area is important for employees and can impact customers' first impressions.

The 5S process involves sorting through items, organizing the workspace, maintaining cleanliness, standardizing procedures, and continuously improving the system.

Implementing a 5S program can lead to numerous benefits:

1. Improved safety

2. Higher equipment availability

3. Lower defect rates

4. Reduced costs

5. Increased production agility and flexibility

6. Improved employee morale, better asset utilization, and an enhanced enterprise image for customers, suppliers, employees, and management.